Hello everyone, I’ve been so busy of late, I’ve not had much time at all to publish any new posts on my blog, with a move to larger premises, and a workshop remodelling, I’m now back up and running to full capacity again.

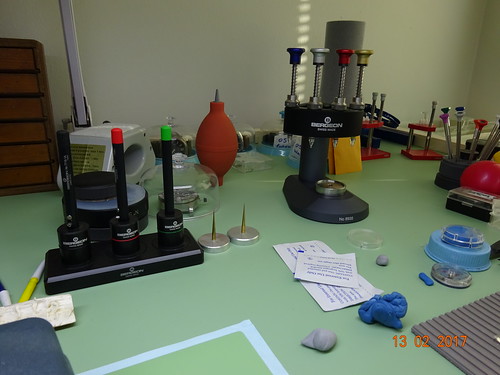

Here’s some photos of my workshop remodel, which started out as 2 x full size office desks, 31″ x 63″, which I have raised to 800mm on two areas, and 850mm on my main working area. A watchmakers bench are usually higher than this, but I find these heights suitable for my needs.

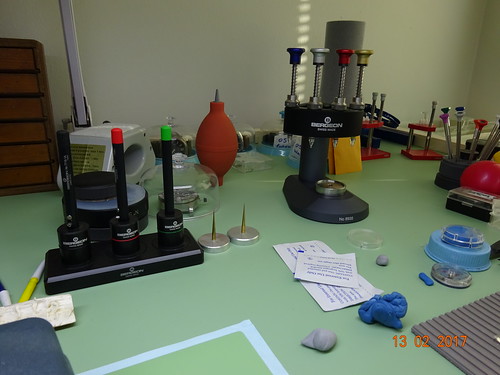

There’s three working platforms, the main central workstation, Timegrapher, Regulating, and Timekeeping monitoring area, and finally, Watch case and bracelet reworking area.

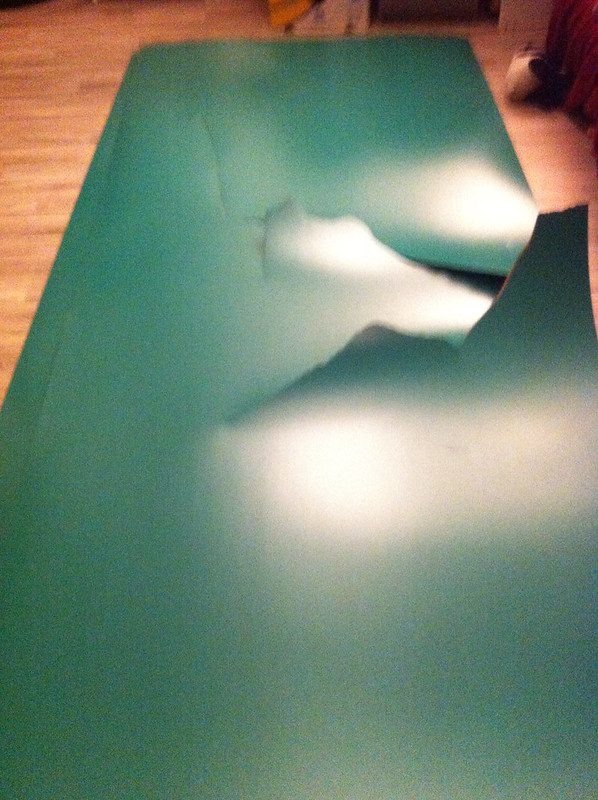

My original plan was to cover all my work tops with the same green covering as my wall units above, this was purchased from the UK, and transshipped to me via a good friend of WRT however, whilst it arrived safely, I was soon to find out that this laminate covering was so brittle, it actually shattered whilst I was measuring it up, and cutting it to size.

Ended up throwing away the two large rolls in the end, and had to come up with another viable option. I recalled seeing another option, but I had originally dismissed that idea due to the covering (same material that small watchmakers mats are made of) was only sold by outlets in the United States, which is odd considering it’s actually made in Denmark.

This material is called ALVIN Vyco 5 ply covering, I found out it was originally made in Denmark, once I had made my purchase, and imported a roll of 31″ x 10 yards. The leading edge of the material is embossed with MADE IN DENMARK.

So whilst I awaited the delivery of the ALIV material, I proceeded to finalise my worktops, which were raised with lumber, 2″ x 2″, and 4″ x 2″.

Once I had raised, and fitted my work tops, I tidied the facias with skirting boards painted white.

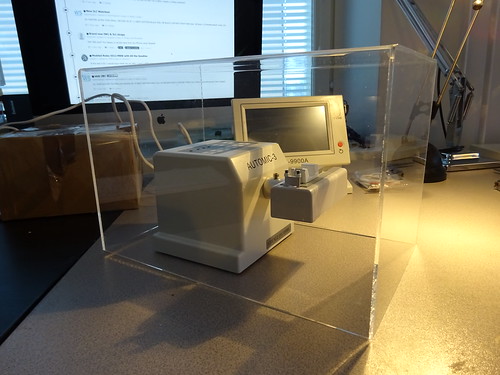

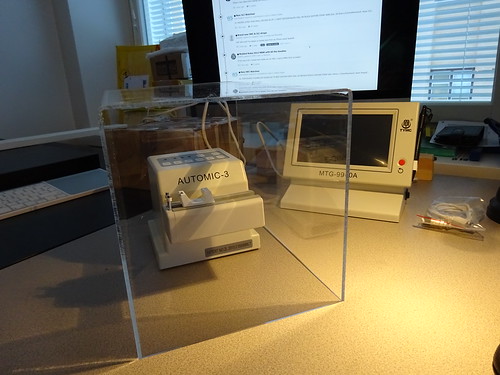

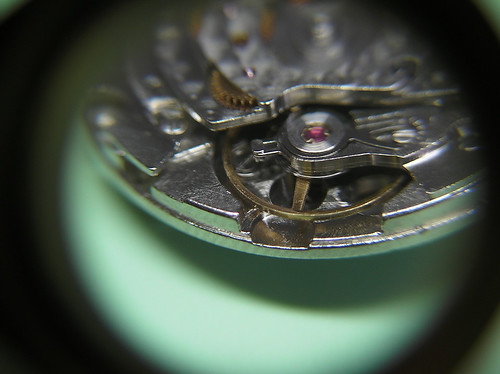

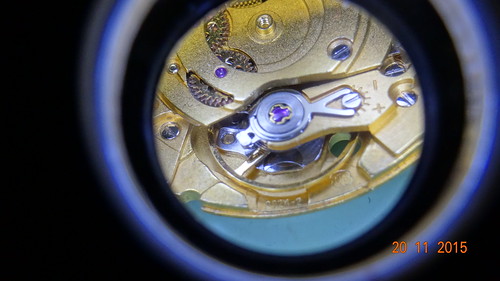

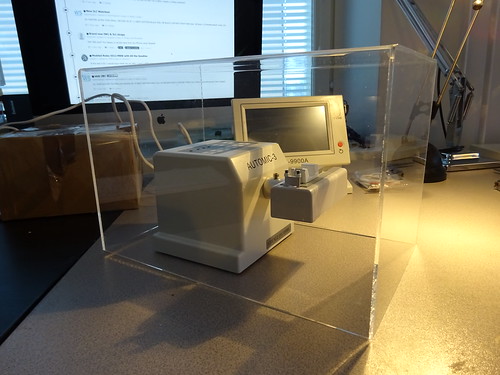

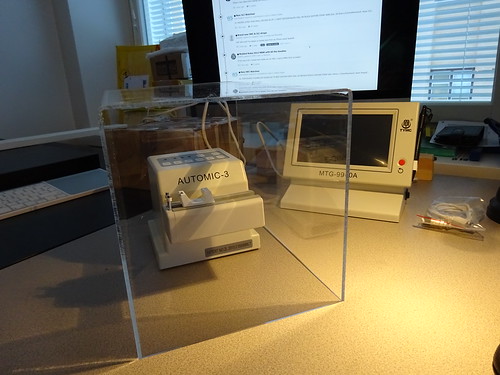

Part of my work top plan was to have a dedicated area, not only for checking timegrapher reading, but also a platform on a pair of sliders for my AUTOMIC-3, the idea for this is to have the ability to push the AUTOMIC-3 back out of the way whilst it carries out the six position tests of a movement, and then to bring the device/platform forward so I could regulate a movement in situ. I also opted for a dust/sound cover. Hopefully the photos will make things more clearer.

First I trial fit the dust cover.

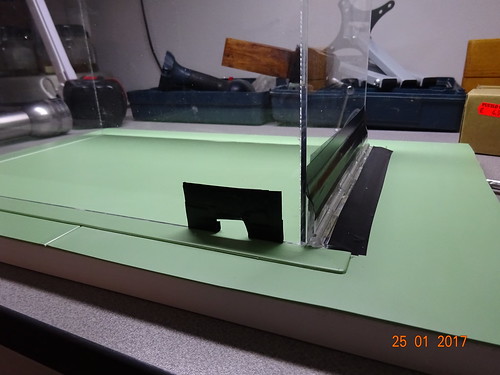

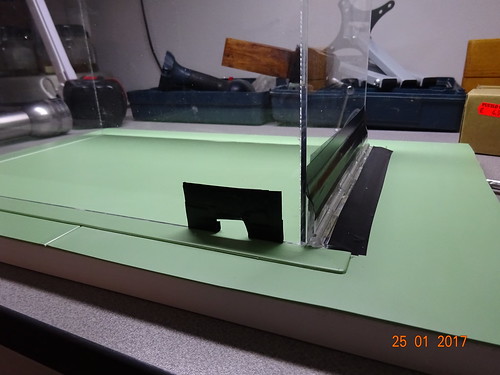

Then a trial fit of the sliding platform.

Securing the rear hinge.

I had originally planned to fit two lifting struts to both aid the lifting of the cover, plus to hold it in place when opened, however, this didn’t work out with the stuts below, they are way too strong and not fitter purpose in this case. I’m on the look out for a pair of lightweight struts.

Cut a hole for the cable routing, this, and the hinge area isn’t pretty, but seeing as it won’t be seen, I went for functional over looks in this area.

I wanted to ensure the cables (Power and Mic) were secure, and to not move the microphone at all when sliding the platform back and forth. I also set up the microphone cable in such a manner that it too would not be stressed from this movement.

The ALVIN covering finally arrived, very excited now, I will finally be able to finish my quest.

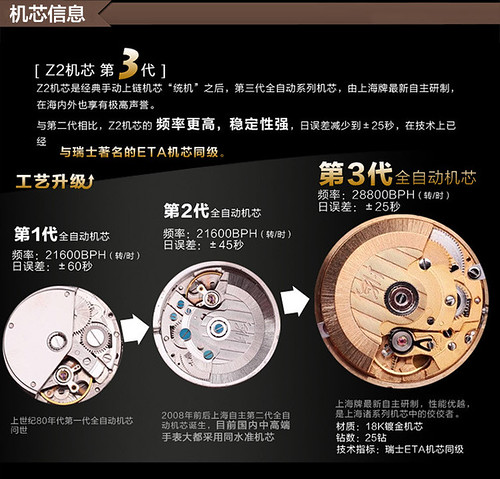

For reference..

Now with the ALVIN here, and having read the fitting instructions, it states that the material is tension rolled, meaning that the material is stretched slightly when rolled, and as such, one needs to measure little oversize for each work top covering, and then having the lay each covering down on a completely flat surface for 24 hours to allow the material to relax to its normal state.

In order to do this, I need to remove everything which has gathered on my work tops.

Individual coverings now cut to a little over the required sizes.

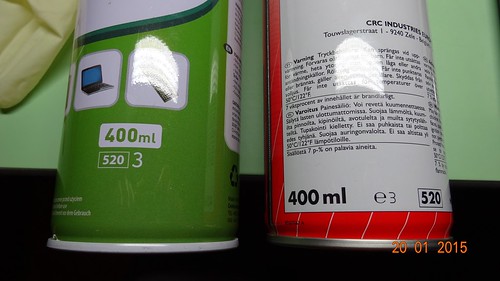

Now I’m glad that I read the instructions that came with this ALVIN covering, as I was planning to use spray adhesive to adhere this covering down, just like I planned with that terrible laminate covering. The instructions advise strongly against this method, and highly recommend to use strong double-sided tissue tape, and only secure along the leading edges. This made fitting very easy.

Once the covering is secured, I then plan to add some balsa wood edging 25mm x 25mm.

Trimming is the final process, and then its ready to work on, that is, once I have finally unpacked all my tools, and equipment.

Here’s the type of slides I used for the microphone platform.

They are low runners, and are usually found on the underside of a full-sized office desk. Seeing as I were no longer using them, I thought of incorporating them into my project.

Balsa wood arrived.

The reason for my choice of using balsa wood is because it’s quite strong, but lightweight, and very easy to work with.

I used a hot glue gun to adhere the balsa to the work tops edges.

Ready to work.

Thanks for reading.